One of our strongest points. We can solve any problems with your grinding process using our cultivated technologies.

Technological specialty: taper processing, centerless processing, high-precision processing (+/-1 μm), cam processing

Work size: φ1 to φ300 mm, Length = 500mm or less

Technological specialty: Small-diameter deep-hole grinding (φ1 mm or more), taper processing, high-precision processing (+/-1.5 μm)

Chucks are all in-house products.

Work size: φ1 to φ200 mm, 7D or less

Technological specialty: mirror finishing, profile grinding process

Work size: up to 600 × 400 mm

We have many machining centers that support high-speed and high-precision processing. We also have 5-axis machining centers with additional 2 axes, which demonstrate their specialty for processing robot parts with strict geometric tolerances and prototype parts for the full cutting of pure materials.

Technological specialty: aluminum high-speed processing, small-diameter deep hole processing (φ2 × 200 mm), grinding processing

Work size: up to 300 × 300 × 300 mm in block, or 600 × 400 mm in plate

Work size: up to φ200 × 400 mm

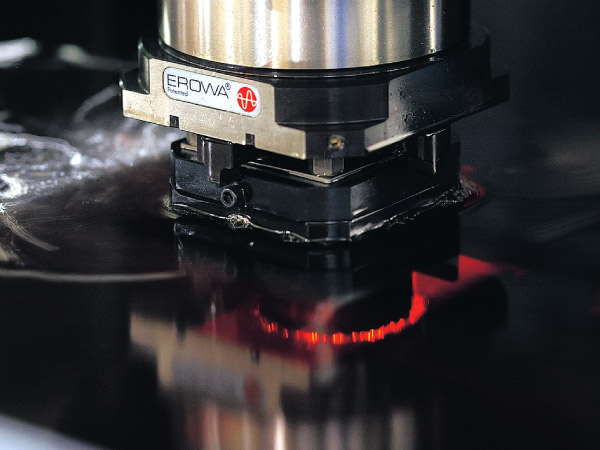

machining(EDM)

Using our original ideas, successful application of wire-cut and die-sinker electrical-discharge machining (EDM) on the machining of parts has been achieved. More difficult shapes, precision, and machining on difficult-to-cut materials can be obtained by using our EDM, instead of other traditional machining process.

Technological specialty: slotted hole drilling (symmetry: 5 μm), slit processing (wire diameter: 30 μm or more)

Work size: up to 300 × 300 × 300 mm in block

Technological specialty: fine hole drilling (φ20 μm or more)

Precision-machined parts are completed only when assembled. We provide total support including precision assurances, leak tests, and operation checks after assembly. Especially, we specialize in bonding, press-fitting/light press-fitting, and shot blasting (aero lapping etc.).

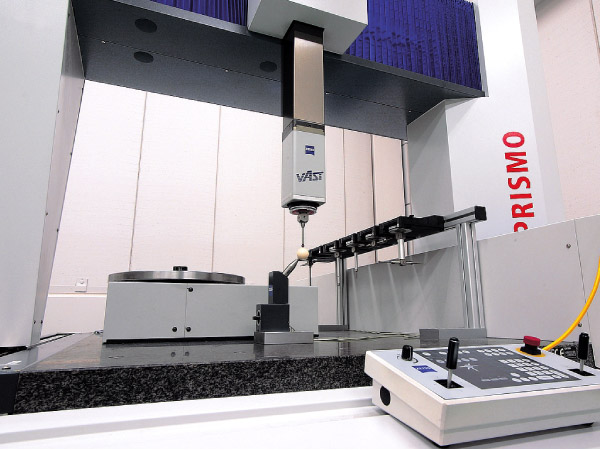

Even if the workpieces can be machined, unless the workpieces is measured correctly, they will lose half of their value. We are fully equipped with various precision measuring instruments, including internationally-valued Zeiss’ 3D measuring machines. Measurement data proves our machining capability that satisfies our customers.

Machining of the parts with a high degree of difficulty requires special tools and thus results in a long lead time. To avoid such situation, we have various equipment for in-house manufacturing of the tools with special shapes, which realize difficult processing and quick delivery.